so ive begun to wire up the ody and its associated components.. i had to really familiarize myself with its circuitry a bit better and see if what i laid out and had in mind was going to actually work.. so far id say 100% ..its a total fucking miracle actually. i was able to get done VCO 1 and its patch points, switches and pcb connections. the breakaway headers offer much better eas of use to remove and fit/test hings and also though, they double the wiring time it takes to each section. but for what they allow its very worth it for me. here are some pics of the prelimary session on the ody..

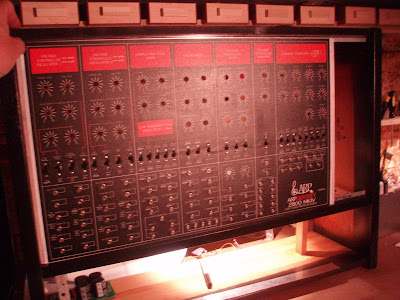

yes. that is a HUGE repro/printout of the PCBS! its fanstatic to have as a reference or as for art! right now its great since i can see component values, traces and component numbers/designations. its ideal.

the face plate and pcbs can be removed seperately and in any fashion/combination really. i wanted to be able to access the inside from either the rear or the front. so , so far this design has worked out really good.